Importance of Mechanical Stability

When it comes to multirotor unmanned aerial systems (UAS), nothing is more critical to a smooth, predictable flight than mechanical stability. While modern flight controllers and onboard sensors can correct for minor disturbances in real time, the airframe itself must start out as perfectly balanced as possible. Two factors dominate that balance: the position of the centre of gravity (CoG) and the alignment of each motor’s thrust vector. If either is off, the controller will spend precious battery power and processing cycles compensating, which can lead to degraded handling, increased oscillations, and shorter flight times.

Center of Gravity (CoG) Management

During the initial design phase, every heavy component—battery, flight controller, GPS module, and camera gimbal—is placed in CAD so that the net CoG falls exactly at the geometric center of the frame. Once that ideal spot is determined, each part is locked into a fixed bracket or slot, preventing even small shifts during assembly that could move the CoG a few millimeters forward or aft.

Then, before every flight, a quick CoG check on a pair of parallel rails or a dedicated balancing stand ensures the craft sits level; if it tilts, a simple strap adjustment or addition of a tiny counterweight brings it back into perfect equilibrium.

Thrust Vector Alignment

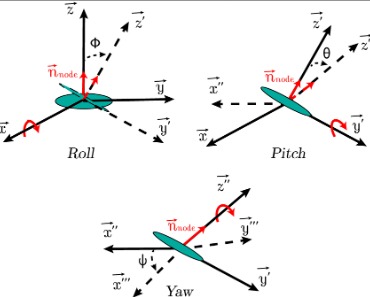

Equally important is the alignment of the thrust vectors. Even with a flawless CoG, a slight tilt in any motor’s output plane acts like a constant lateral push, forcing the flight controller to trim out the drift continuously.

To prevent this, builders mount the UAS on a known level surface—ideally verified with a calibrated spirit level—remove the propellers, and spin each motor at low speed to confirm that the thrust plume exits straight upward. If one motor’s thrust is angled, shims under its mounting plate or a slight tweak to the arm’s squareness corrects the misalignment.

While most flight controllers offer software “tilt compensation,” it should always be a last resort; mechanical precision on the bench yields the most responsive and energy-efficient flight.

Conclusion

By fixing the CoG at the design point, locking down component positions during assembly, and carefully leveling every thrust vector, you give your PID tuning a straightforward canvas on which to work. The result is a UAS that hovers rock-solid, responds crisply to stick inputs, and wastes no effort fighting hidden imbalances.

In the demanding world of unmanned flight, taking those extra minutes on the workbench makes all the difference between a power-hungry, twitchy drone and one that glides through the sky with effortless stability.